Compact education CNC lathe, the most space-efficient CNC machine designed for educational settings. This compact, small education CNC lathe is the ideal introduction to CNC machining for students, capable of performing intricate turning and high-precision small part manufacturing.With an industry-standard SINUMERIK 808D control, allowing students to gain hands-on experience with the same technology used in professional settings. With the ability to cut light materials and turning metals, this machine bridges the gap between classroom learning and real-world manufacturing, preparing students for high-wage, high-demand careers in advanced manufacturing.Equip students with practical skills and experience using the same control systems found in the industry,prepare students for the workforce with hands-on experience in modern machining and manufacturing processes.

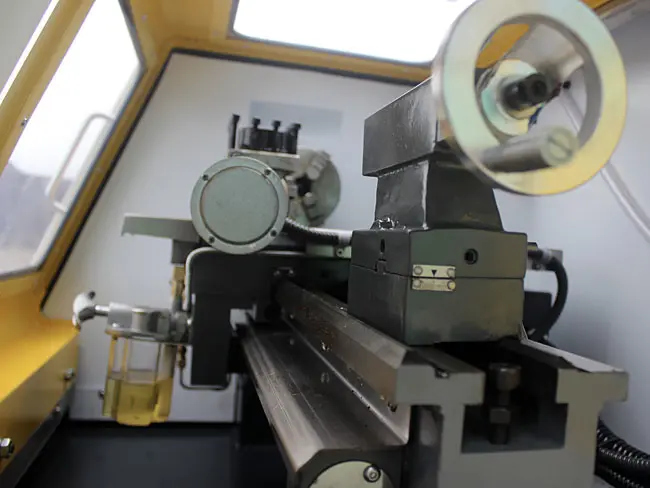

100mm 4 inch self-centering,optional 4-jaw chuck.Use cast iron spindle box,It has good rigidity and stability, which benefits to the machining precision.Spindle with encoder, capable of turning threads.

This machine is designed with a guide rail lubrication system, for extended machine lifespan.

Our large-capacity circulation cooling water tank, equipped with a filtration system, effectively dissipates heat and removes impurities, ensuring optimal performance and extending the lifespan of your tools . With manual and g-code automatic control.

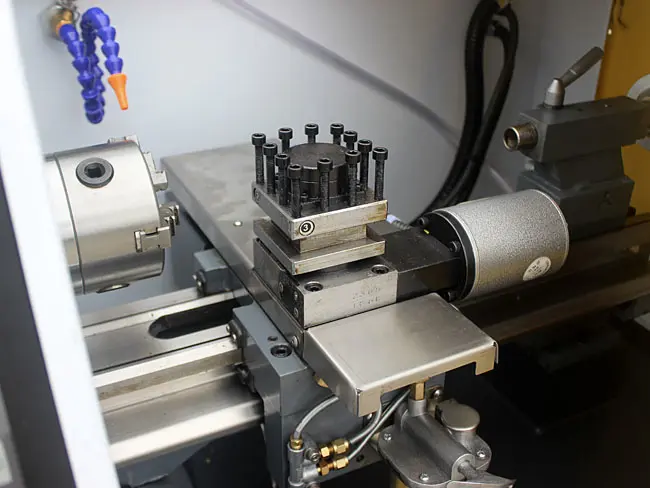

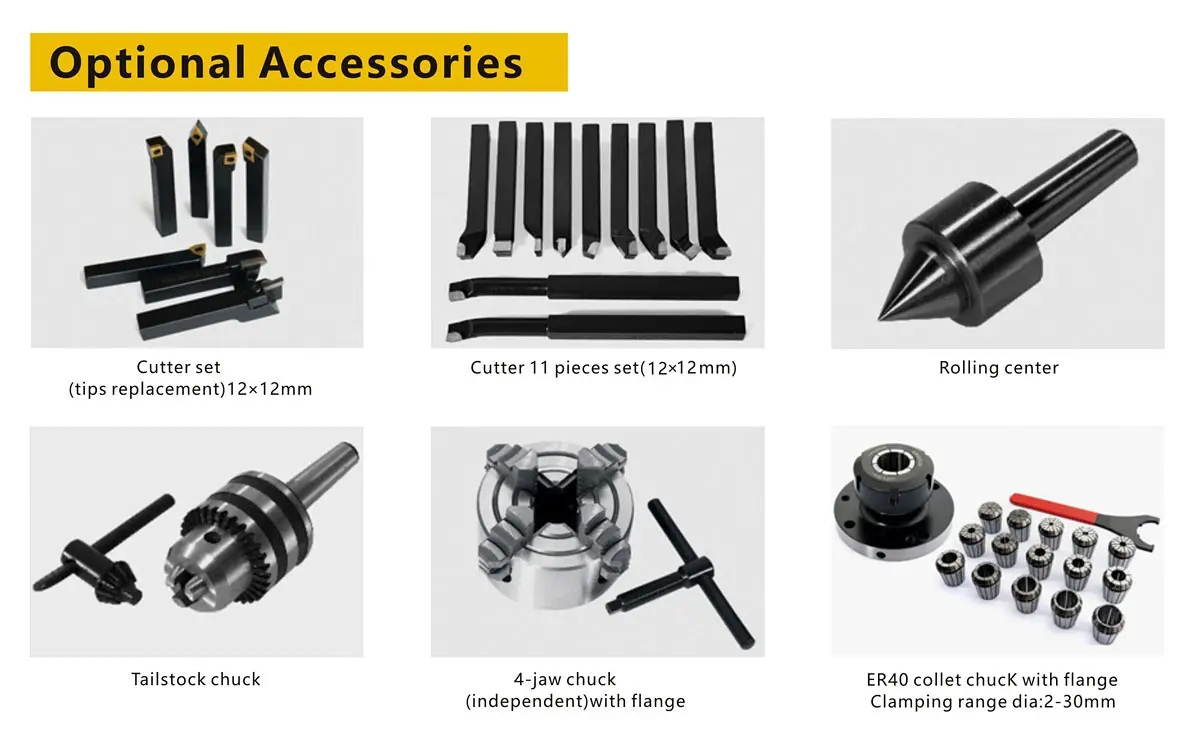

Equipped with a 4-station automatic tool change for processing more complex parts,optional 8-station automatic tool change.Turning tool specifications is 12*12mm .

SINUMERIK 808D ADVANCED brings impetus into basic turning and milling machines. CNCs from the global technology leader, teamed-up with a revolutionary operating concept make the SINUMERIK 808D ADVANCED the perfect entry into the world of CNC.

Machine tool bod selection of high-quality casting materials,with lathe tailstock,semi-automatic lubricSation system,protect the rail life and ball screws for unmatched precision.

Technical parameters |

||

Description |

Standard |

Optional |

Positioning accuracy: |

0.02mm |

|

Repeatability accuracy |

0.03mm |

|

Control system |

SINUMERIK 808D |

FANUC Series Oi-TF Plus |

Automatic tool change system(ATC) |

4 Tools |

8 tools |

Turning diameter over bed(max) |

210mm |

|

Chuck diameter |

100mm |

|

Spindle speed |

300-1800r/min |

|

Spindle through-hole |

26mm |

|

Spindle mount |

MT4 |

|

Spindle motor power |

1100W |

|

Work-piece cooling |

Water Cooled /29L |

|

X axis travel |

90mm |

|

Z axis travel |

300mm |

|

X/Z axis motor |

400W Servo Motor |

|

The max moving speed |

8000mm/min |

|

The max feeding speed |

4000mm/min |

|

Full cast iron |

Full cast iron |

|

MPG handwheel |

4 axis |

|

Tool dimension |

12×12mm |

|

Tailstock taper |

MT2 |

|

Tailstock sleeve diameter |

20mm |

|

Travel of tailstock |

25mm |

|

Power |

380VAC (3 Phase) |

|

Weight(NW/GW) |

280/320KG |

|

Overall dimension |

1250×700×1300mm |

|

Packing size |

1400×860×1500mm |

|