YORNEW's VMC200-FANUC small education CNC mill machine offers a small footprint,it provides full CNC capabilities in a compact space. Moreover, this efficiently competent small CNC mill comes at an affordable price,with Fanuc Series 0??-MF Plus controller,selection of high-quality casting materials,high-precision linear guide and ballscrews,automatic lubrication system.Option 5 tools automatic tool change system(ATC), frequency conversion water cooling spindle motor, low noise, 24000rpm spindle supreme speed.Standard spec XYZ axis is AC servo motor.With the of flood coolant with industrial cabinet base and and automatic aligning instrument.It can process ferrous metal stainless steel, 45 steel, non-ferrous metal copper, aluminum, plastic and wood and other different materials.Suitable for ocational technical college Education & Training CNC.

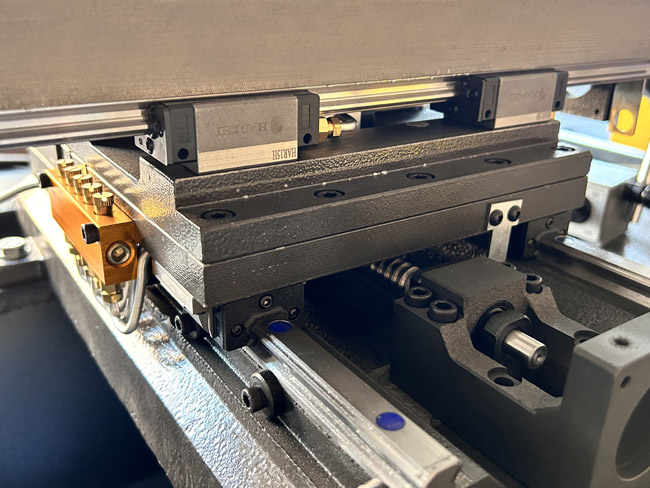

Machine tool bod selection of high-quality casting materials,high-precision linear guide and ballscrews,automatic lubrication system,protect the rail life,experience the pinnacle of precision, reliability, and longevity with our small CNC mill machine, featuring a high- quality casting materials for unwavering rigidity, high-precision linear guides and ball screws for unmatched precision.

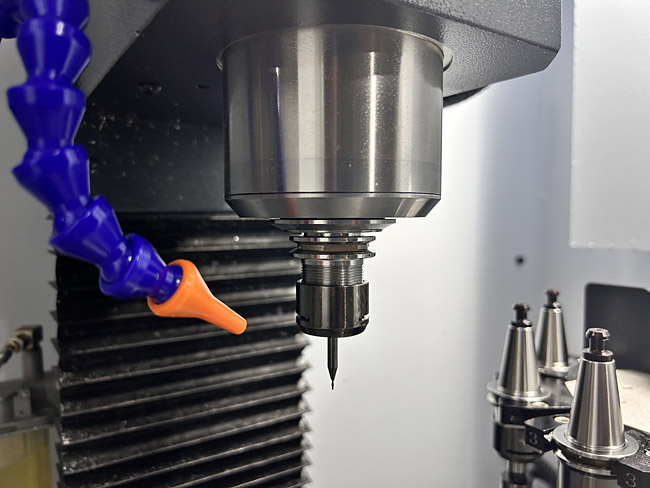

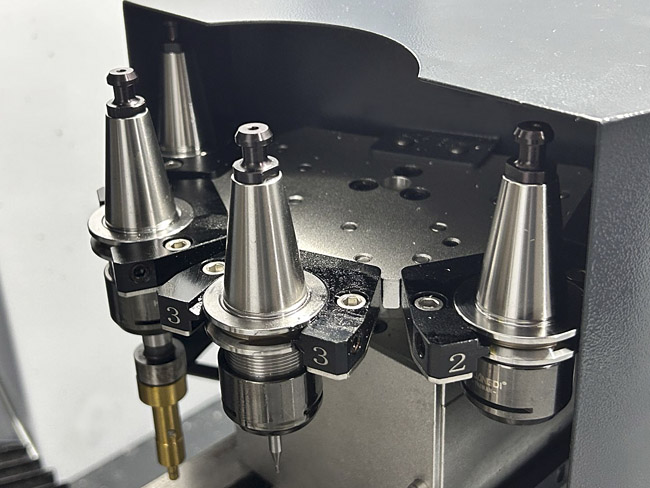

Our high-performance spindle delivers exceptional power and versatility, catering to a wide range of machining needs. The variable-frequency drive allows for precise speed control, optimizing performance for specific materials and applications. With manual and automatic tool change capabilities, our control system adapts to your workflow, empowering you to achieve operational excellence.

The robust 5-station self-locking rotary tool carousel safeguards against misoperation, while the protective dust cover ensures that machining accuracy remains uncompromised. Experience the pinnacle of precision with our water-cooled spindle, variable-frequency drive, and pneumatic tool change, ensuring consistent performance and unwavering accuracy.

The Fanuc Series 0??-MF Plus provides the ideal solution for basic milling applications. This system is equipped with the latest control technology for fine surface machining, reducing cycle time, and customisable functions that can flexibly create screens suitable for machine tools.

Our large-capacity circulation cooling water tank, equipped with a filtration system, effectively dissipates heat and removes impurities, ensuring optimal performance and extending the lifespan of your tools and spindle. With manual and automatic control options, our system adapts to your specific needs.

Support high precision Z Axis Setter,industrial-grade automatic tool setter,make it easier for you to operate.

Technical parameters |

||

Description |

Standard |

Optional |

X axis travel |

230mm |

|

Y axis travel |

130mm |

|

Z axis travel |

220mm |

|

A axis travel |

/ |

360° |

Spindle taper |

ER20 |

ISO20 |

Automatic tool change system |

/ |

5 Tools |

Pneumatic supply |

/ |

0.6 MPa |

Tool DIA. range |

1-13mm |

|

Control system |

Fanuc Series OI-MF Plus Controller |

SINUMERIK 808D |

Spindle power |

2.2kw |

|

Spindle speed |

100-24000rpm |

|

Spindle Cooling |

Water Cooled / 10L |

|

Work-piece cooling |

Water Cooled /29L |

|

XYZ axis motor type |

400W AC server motor |

|

Rapid feed rate |

10000mm/min |

|

Cutting feed rate |

5000mm/min |

|

Positioning accuracy |

0.02mm |

|

Repeatability accuracy |

0.01mm |

|

Transmission |

ball screw |

|

guide rail |

High-precision linear guide |

|

Table size |

460*130mm |

|

Number of T-slots |

3 |

|

T-Slot Width |

12mm |

|

Max Weight on Table (evenly distributed) |

30kg |

|

Table structure |

Full cast iron |

|

Power |

380VAC (3 Phase) |

|

Weight(NW/GW) |

250/350kg |

|

Overall dimension |

980×740×1600mm |

|

Packing size |

1100×800×1800mm |

|